The packaging industry makes use of different types of packaging methods and strapping or banding is one of them. Strapping involves the use of special tools and specific types of straps made to be used with said tools in order to seal and attach items to pallets skids and even crates.

Strapping is mainly used in vertical and horizontal bands and thus it’s best for closing corrugated boxes and securing coils made of paper or steel. You can use it to hold down bales of textiles or any agricultural product as well as to reinforce wooden boxes and to secure packaged glass. This especially goes for stainless steel strapping and banding.

Advantages of Stainless Steel Strapping and Banding Tools

Corrosion

The number one reason why you should go for strapping and banding tools that use stainless steel straps is that they won’t corrode or rust that easily. Corrosion is something that even stainless steel strapping and banding tools are not going to be affected by. That is if you take care of them properly.

Strength

Something that is common with all types of metal is their excellent strength levels. The same goes for stainless steel banding and strapping which is why it’s used to secure large heavy items. Stainless steel can withstand extreme amounts of pressure and heavy impacts so you won’t have to worry about your items getting damaged or boxes getting opened as easily.

Longevity

Since fending off corrosion is no slouch for stainless steel strapping and banding tools, it means that they have a long lifespan. That definitely is the case especially if you use 316 stainless steel strapping as it has a more alloy-rich mixture than 306 stainless steel strapping.

Environment

Stainless steel as a material is actually good for the environment. While it does cost more than regular steel and other types of metals, it definitely is a more recyclable material than most. This is also why people tend to go for a stainless steel banding tool too.

Types of Stainless Steel Strapping and Banding Tools

Cutting

As you’d expect stainless steel cutting tools are made to cut the strapping or banding when you’re finished securing the box or crate. If you use heavy-duty stainless steel strapping or banding, then you’ll need such a stainless steel strapping tool too as otherwise, you won’t be able to cut the strapping/ banding. Also, banding is cut when you need to get rid of excess material that’s hanging off and not just for applying closure.

Tensioning

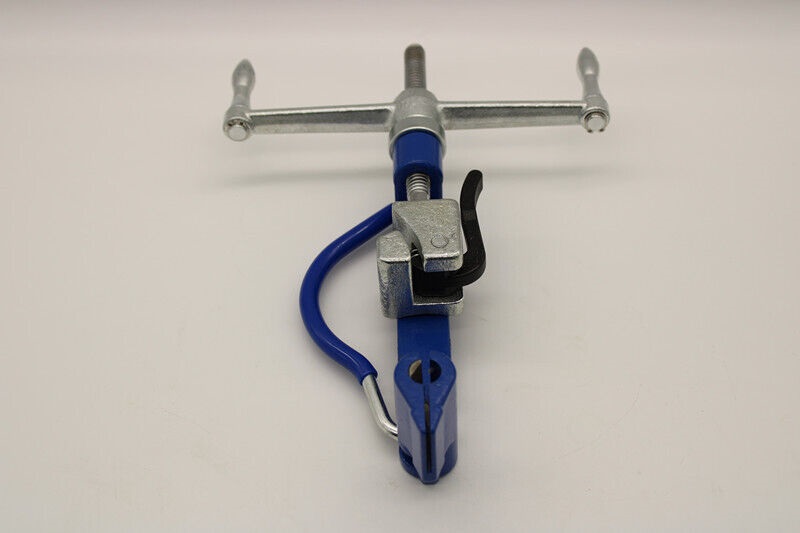

Talking about applying closure, you also need to use a tensioning tool. With this type of stainless steel strapping tool, you create enough tension so that the banding is nice and tight on the item. Without such a stainless steel banding tool you won’t be able to secure the item as well and there will be a risk of the box or crate opening while being transported.

Crimping

A crimping stainless steel strapping tool is only going to be necessary if you’re using pusher seals with your banding/ strapping, otherwise, you won’t need them at all.

Important Factors of Stainless Steel Strapping and Banding

Thickness

The thickness of stainless steel strapping and banding will determine how heavy of a load it’s going to be able to hold together. The thicker it is the more heavy-duty strapping you have. But keep in mind that thicker strapping/ banding is also heavier. Meaning it can be an overkill solution for a light load. Make sure to not always go for thicker strapping/ banding as it’s not always going to be necessary.

Width

The width of stainless steel strapping/ banding is going to play an important role in the size of crates and boxes you’ll want to secure with it. The bulkier they are the thicker the strapping/ banding material that you’ll need to go for. This makes the material cost more, but it also makes it stay in place even when under lots of pressure simply because there is more of it to hold down all that weight.

Closures

Stainless steel strapping and banding tools also make use of closures. These accessories are as important as the tools and the strapping/ banding itself. Why? Because they seal up the strapping at the end where you apply pressure with the tensioner and use the cutter to take off excess material.

Stainless Steel Grades

201

Different stainless steel grades offer different capabilities and starting with 201-grade stainless steel you have fairly corrosion-resistant material. It’s definitely not going to surprise you in any way but it’s going to be the most bang-for-buck solution as it’s harder and stronger than 304 and 316-grade stainless steel.

304

When it comes to 304 stainless steel strapping/ banding you can expect it to have excellent corrosion resistance coupled with an equal break strength as that of 316 stainless steel. This is the most widely known stainless steel grade.

316

Also known as marine grade stainless steel, 316 stainless steel is the best at fending off corrosion. Not only that, but it’s also good at surviving chemicals, salts and acids quite well.